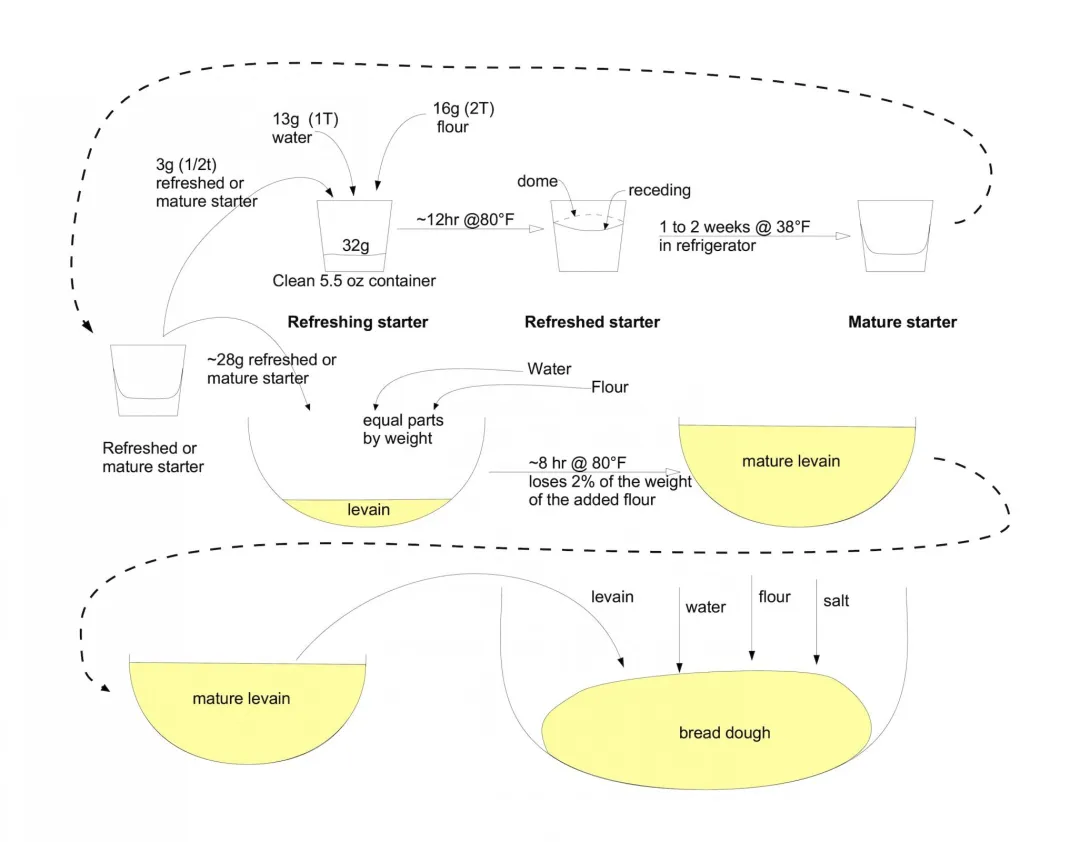

Since the facility for uploading fully formatted Word and PDF documents has not been implemented, the details of this post can be found here and I have loaded (above and below) a pictographic shorthand version which lacks any explanation of the rationale. The artwork covers the whole bread-making process of which the illustration above covers starter maintenance, elaboration into a levain, and then using the levain to initiate a batch of bread dough. The linked paper covers only the starter maintenance and elaboration aspects of this process. The remainder of the complete bread process is included in the illustrations below.

One point I want to make here is that you don't need to keep a lot of starter, even if you want to make a lot of bread. Using the quantities noted below, you are keeping about 30g of starter, from which you use 3g to seed a refresh cycle and either throw out the remainder or use it to make a levain, from which you will make a batch of bread.

Many sources would have you keep at least a cup of starter (or a pint, or a cup in a pint jar, or a pint in a quart jar) which is totally unnecessary. If you are going to need 10Kg of levain, you can elaborate 20g into 10,500g in two steps (or 3g into 10500g in three steps), building 20g into 500g of refreshed starter by feeding it at 20:250:250 (a factor of 12.5) and letting it ferment for 6 to 12 hrs depending on the temperature and repeating the feeding to expand it by another factor of 10 (500:5000:5000) to yield 10.5 Kg of levain. So your little 5.5 oz polypropylene food service cup containing 28g of starter becomes 10.5 Kg of levain in 24 hrs. By doing this and assuming that you feed it every day (which is one option though once a week is enough to maintain it if you don't need bread during that time) you throw out starter containing ~16g of flour every day. That is a total of over 5.5Kg of flour in a year which is not trivial, but it does make for a pretty inexpensive hobby - or you might perfer to think of your starter as a pet which doesn't eat nearly as much as a dog. If you maintain a pint of starter and feed it 50g of flour daily you will need 18Kg of flour over the course of a year in addition to the amount you use to make bread. And you have to figure out where to throw out 100g+ every day (which should never go down the drain since it will eventualy coat your drain line like hundreds of layers of paint and irretrieveably plug it up).

You can also read the blog post down below the one about idli that explains the The 2% weight loss method for judging levain maturity (which you can also use for your starter if you have a high accuracy scale).

- Doc.Dough's Blog

- Log in or register to post comments

Thanks for sharing. The flow chart is very easy to follow and understand. It clearly shows the difference between maintenance and levain builds, often overlooked. I am a great advocate for constructing flow charts and link charts when trying to understand complex topics, particularly when rationalising multiple sources. They are great for refreshing and reviewing and often highlight knowledge gaps.

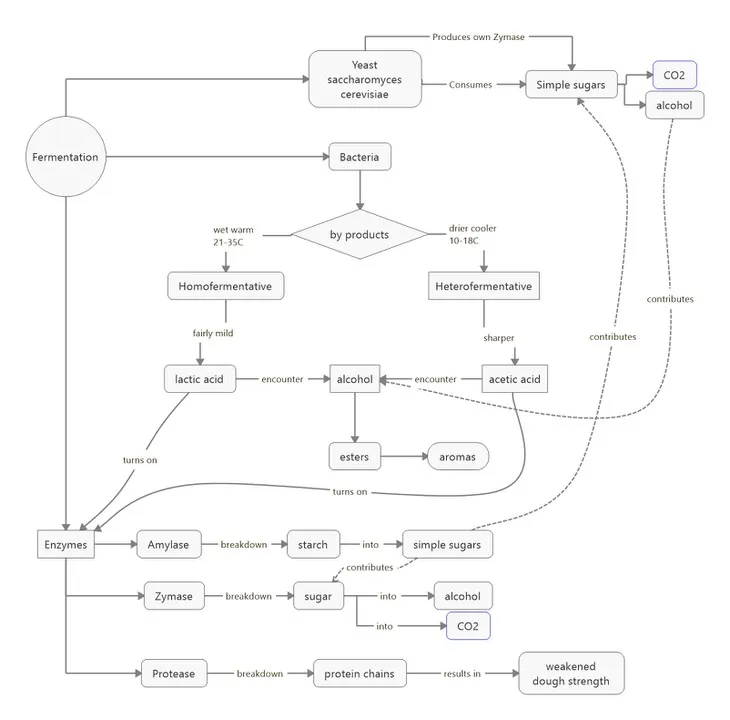

Here is one I did when understanding fermentation (Let me know if there are any issues):

Cheers,

Gavin.

Excellent! Bookmarked.

@Doc: This should be terrific for graphically-minded newbies, to be sure. Clear and logical. Starter maintenance amounts are uncannily close to my practice, so 👍👍 for that. However I did note some long fermentation times. 12h @ 80˚F is 2-3x the treatment my starter needs to be refreshed to seed a levain. While an over-fermented starter is a minor misdemeanor, a geriatric levain can be a felony and 8h @ 80˚F is about twice what my levains need to be doubled and domed. From my decidedly Robertsonian mentoring, youthful levains make better doughs and breads. ymmv.

@Gavin: Another useful graphic. But what's a "Zyme"? I can imagine apostrophic 'zyme as a contraction of "enzyme" if one fears life too short to waste on unnecessary syllables. I even googled "zyme" without pertinently satisfying results. In your chart, it assumes the place of enzymes that hydrolyze sugars. As a (retired) biologist, I've never referred to such molecules as "zymes". New terminology? Seems like the place for maltase, invertase, hexokinase et al..

Tom

@Tom & @Gavin.

I'm guessing Gavin meant Zymase.

Or he was pluralising the Greek word "zyme"

I, unfortunately, made a typo twice; indeed it should read Zymase. Just shows that one should cross-check even an Aide-mémoire.

Thanks for pointing it out.

Cheers,

Gavin.

Amended Chart:

Image

Thanks to Doc.Dough for some valued feedback regarding my fermentation chart. I have updated the chart that incorporates Doc's input and adds further detail and understanding.

Cheers,

Gavin

Thanks, Doc. Always learn when you post.

Nancy

Thank you Nancy!

Yes, a lot of starter info on the web seems really misleading. I keep a small amount in the fridge and refresh before use, typically once every 1-2 weeks. I used to feed the night before but I can even feed the starter on the day of building a dough and simply put it in a warm place, take what's needed, and put the rest back in the fridge.

I've used up most of my starter sometimes and been left with maybe 5g or so to put in the fridge which is plenty to feed and build up again as needed.

So no discards for me, no feeding other than before a levain build, and only keeping a small amount in the fridge. Life is pretty simple.

I use 100% dark rye starter which seems plenty powerful.

Hi Doc. Can you explain why it is beneficial/necessary to build a larger levain to make the bread, instead of simply using the small amount you would usually discard from you starter?

If I tried to make a 3500g batch of bread (or even a 1700g batch), 29g of starter would would take forever to bulk ferment, and since life is short I prefer to use about 12% pre-fermented flour. You can do the math, but that means I need a lot more levain than I ever have leftover starter.

Is time to ferment the main reason? If you add the starter straight to the dough, wouldn't the time to ferment be equal or less than the sum of the time to make the levain and the time to bulk ferment?

Since I can make up as much levain as I need in 12 hours (or so), I can always plan for X-hrs to make the bread I want (irrespective of whether it is a small batch or a large batch). X seems to vary from 7 to 9 hours over the course of a year. So if I plan to make bread tomorrow I refresh the starter today at a time that is sufficient to allow the intended levain to mature by whatever time I want to start making bread in the morning (the window of usability for levain is probably around 6 hrs so it is not very sensitive). Refreshing the starter and mixing the levain takes about 15 minutes by the time I clean up so that is a fixed investment. From there it is just muscle memory to make a batch of bread tomorrow in 9 hrs (this time of year). Since bulk fermentation is approximately an exponential process, the exact time becomes harder and harder to predict/control when it is further in the future. A two step process converts it into one exponential process that is pretty insensitive to when you elect to terminate it (and proceed to making bread), followed by a second exponential process that is routinely predictable if you control the temperatures and ratios. Of course you can make bread from a small bit of starter and a lot of flour, but the end point of each unique trial will be both different and unpredictable. Could I do it that way? Probably (and for a particular formula I do use a 1% PFF and a precisely controlled DDT and BF temperature). But why? Making my life easier takes precedence. Thus timing is the primary reason.

You seem like you know what you are talking about. I wonder if you would be able to help me. I am feeding a rye starter every day using Hamelmans method from his book. 10g starter, 20 g water, 16 g flour - it is pretty pasty consistency, it does well but then starts getting the kham yeast and it really bothers me. I tried with starter from friends who did not have this problem, but after a while of feeding it this way, it start forming the white powder on top again. Any idea what might be wrong?

The bread looks and tastes good

I am using organic rye flour from Central Milling, spring water, clean glass jar each day, I store my pre-measured flour and water in small glass containers for the week.

Any help would be appreciated.

Describe exactly what your process is. The Kahm yeast should not grow as fast as your starter does so something is wrong. Perhaps pour off the top layer of starter and take your sample for the next feeding without getting any of the surface yeast. What are your temperatures? How long between feedings? (10:20:10) may be your problem. Try (3:14:17) and let it run for 12 hrs before feeding again (assuming 78°F fermentation temperature). Take photos of the starter at 4hr intervals. Do you have a milligram scale? If so weigh the starter every hour so that we can see when it is growing (do not deflate the starter, just weigh it) and when it stops growing. A feeding at (3:14:17) should weigh 34g more than the container just after mixing, and should lose about 340mg of CO2 over 12 hrs.

This is helpful, thank you, I will follow your procedure and will start from a friend's starter again. My feedings are every 24 hours (the way hamelman described his) I have not measured temperatures yet (I am doing this for 4 years and only last year started to have this issue, so I did not think of checking the temperature). I take 10 gram of the starter, add water and 100% rye flour, mix and let feed for 24 hours. at 12 hours, it seems to have the most volume, but by the end of the day, when I feed it again, it has decreased size to two thirds of the full volume. Some days are fine, it looks dry on the surface but no yeast, but others are completely white on top. I then scrape off the top, take 10 grams from the bottom and start again.

I don't have mg scale, but I am going to invest in one if only to get the hang of it and learn to do it well. Appreciate this. Will report back soon

I also feed my whole rye sourdough culture using Hamelman's method and have done so for about 5 years. I feed it every morning around 7 am and it lives on the bench in our kitchen. Mine also gets a very light frosting of white on the surface. I've assumed that it is an indicator that the culture needs feeding. It doesn't seem to affect the culture's performance.

I have had Kahm yeast show up on sauerkraut and on injera batter. Both seemed to indicate that the fermentation had gone to completion and the Kahm yeast was able to get established on the surface. My theory is that the feeding cycle is too long as the normal yeast should be growing faster than the Kahm yeast. It is aerobic so keeping the container sealed and allowing CO2 to flood the ulage volume should suppress it, but the ullage volume needs to be small and the container needs to be tightly sealed. For sauerkraut I generally add a high salt brine to isolate the Kahm yeast then pour it off, remove some sauerkraut, and wipe the side of the container before adding back some 5% brine. Since the primary fermentation is complete by that time, the higher salt content is not going to slow down the fermentation but should prevent the Kahm yeast growth. For sourdough starter that is not likely to work, but it might be OK to add enough brine to lift the exposed surface and allow the yeast to be poured off, after which you can take a sample from below to try a re-start. You might try using a bulb baster to remove a deeper sample without disturbing the surface:

Put a paper towel plug in a funnel so that it protrudes out the bottom. Plunge the tip into the surface then pull out and discard the plug. Now insert the bulb baster through the now open hole in the funnel, bubble a little air in the process and remove a small sample.

I posted about a similar problem a while ago.

https://www.thefreshloaf.com/node/74627/yeast-film-rye-starter

It seems to me that this problem only affects 100% rye starters. My wheat starter shows no trace of it. However, I suspect it can affect starters using any type of rye flour, from white rye to wholegrain.

I haven't been able to cure the problem, but I keep it at bay by feeding once a week in a slightly tedious 2 stage build and storing in the fridge. A direct effect of the problem is that the normal acidity you would expect with a stored starter is lost - a little taste after storing for a week displays no acidity, even though there is an acidic taste at the start of storage.

Any longer than a week in storage and my starter starts to smell unpleasant and you can see the yeast film.

And yet the starter makes good bread when refreshed and used to bake.

Lance

I found a reference that suggests that under some storage condidions rye flour (some) may harbor Kahm yeast and display a white to cream colored surface that can be removed. Sounds like a water availability issue requred to support growth. Which suggests that storing rye flour with a dessicant pack might be a good idea if you are seeing the issue. It also suggests that not all areas or all seasons would experience the problem.

This a photo at 24 hour feeding. 12 hour feeding is almost double that volume, so you are most likely right that it was being fed too late and with each cycle, I probably have a poorer mixture of yeast and LAB in there. I will also find a smaller container and have it air tight. The storage container and the flour is looking OK, but I have never washed it after changing a batch, will do that now and try a different mill to purchase from. I am encouraged by everyone posts and their experience with Kham, it is starting to make sense.

There is no such thing as too clean when working with biology. When you get ready to feed, I would probably try to move the surface material away from a spot where you are going to take a couple of grams of seed for the next cycle, then as soon as that sample doubles, forms a dome and begins to recede, do it again. Each iteration should reduce the amount of Kahm yeast that you have in the batch. If you reduce it by 10X each time, and repeat it 7 times the net reduction is ~10E7 (10,000,000) which might be enough to get rid of it if your sample size is small (probably not but possible, and it should certainly delay a recurrence).

Here is a photo of a starter sample in my standard growth container. They are 5.5 oz food service cups with lids. I buy them at Smart&Final by the 100 (cups and lids separately) and use them for lots of things. In a sous vide tank I put a 2" x 3/32" washer in the bottom of one to hold and stabilize another one containing starter. The washer acts as ballast to keep it stable as it floats in the warm water. The lid fits tight but not so tight that CO2 can't get out. I offer this as an example of a way to always have a clean cup available when you feed your starter. In this case it was 5g of seed starter and 14g each of water and flour making ~33g total. I write the label on blue tape and align the bottom of the tape with the top of the starter after it has been fed when it begins its fermentation. The starter will grow about 3X over 12 hrs (depending on the temperature, starter health, and flour:starter ratio. I always use at least 2X flour:starter ratio) and preferably >3X and sometimes as much as 30X though ratios that are too high put you at risk of contaminants out-growing the good guys.

Greenchive - What is your local climate? Cool/humid? Warm/humid?

Thank you - midwest Indiana - mostly humid in the summer, but cool in the winter - home temps around 70-74.

I suspect that the indoor humidity is relatively low if the heat is on so it may take more than just cool weather to discourage Kahm. It seems to grow faster at higher temperatures but I can find no credible data on an upper limit that inhibits Kahm growth. But you might check your rye flour storage container under a bright light and see if you observe any surface growth of Kahm. You might want to try a different source of rye flour as well.

I read with interest your comment that Kalm yeast is aerobic. When I refreshed my whole rye sourdough culture yesterday morning, I laid a small piece of cling film directly on the surface of my firm rye culture. The film of Kalm yeast did not grow as usual and was significantly reduced.

I feed my culture with stone milled whole rye that I mill weekly. I vary the culture feeding slightly depending on the season. I leave it on our kitchen bench and feed it every morning.

That is a great idea! I assume that for a stiff starter there will still be places around the edge for O2 to get under the film. So I wonder if a layer of cling film over the surface, topped with a little 5% brine might be even more effective. The brine would seal the edges from O2 penetration and inhibit Kahm growth (we think) and the film reduces the surface area over which the brine might diffuse into the starter and mess with the growth process you are trying to encourage.

Then pour off the brine, maybe even flush with a little fresh water, pull off the cling film and slice into the starter, pushing back the cut edge so that you can access clean starter. Take a sample from below the surface and feed it in the same way. After a few cycles perhaps you can just take a sample from under the cling film.

Thanks. I'll give it a try. I'm encouraged by todays result.

Cheers.

I am excited to read the result of your experiment. Doing the same today. Thank you for sharing

Report back when you can. Until reading this thread, I didn't know about Kalm yeast, I just thought it was a sign of needing a feed.

Opps. I was just feeling very calm.

I haven't tried the brine addition as yet but can report that my rye sourdough culture is no longer showing any signs of the Kahm yeast on the surface. I have a small, upturned glass that stretches the cling film across the surface and is a better seal around the edges. Will the kahm yeast get eradicated over time or lie dormant?

You have become the lead on this so we are waiting for you to enlighten us. My guess is that it will lie dormant. But as you repeatedly refresh the starter taking samples from below the surface, the Kahm population will become diluted. More so if you are surgically about taking samples. You might want to open a new thread focused on Kahm yeast and perhaps recruit some experimentalists to do some of the work.

I was thinking of getting an option from Debra Wink with her expertise in microbiology. I'll send her a message. Cheers, Gavin

There might be a salt concentration that discourages Kahm but does not fully suppress the yeast and LAB associated with your sourdough. The experiment I might run would be to set up a few (maybe 5) parallel samples of starter refreshed with different salt concentrations. Maybe zero (your control), 2%, 4%, 6%, 8% and 10% with the salt added after the starter has been fed and divided into separate containers. Hold them at the same temperature and take daily photos of the surface watching for both volume growth and the development of a color change. If you can arrange to take the photos under the same lighting you might be able to use a color characterization app (e.g., WhataColor?) to detect a color shift.

I like this scientific approach. It might even delay the growth to peak at 24 hours.

I would expect that the growth rate would slow down as you increase the salt concentration and around 8% it might stop all together (or not). Once you have that data you can design another set of experiments to set your fermentation temperature. Do you have a sous vide circulator?

I have a bread proofer so I can control the temperature that way.

You might also try heating some of your rye flour to 140°F on a half sheet pan and holding it there for a couple of hours (stirring every 15 minutes) to fully dehydrate it. Measure the weight loss and calculate the water content of the flour in storage. Now use the dehydrated flour to feed your starter. The elevated temperature might be enough to denature the Kahm yeast or at least reduce it's activity. This is a long shot but you will at least know what the moisture content of the rye flour is in your cupboard. And while you are doing that it is probably worth while repeating it with some white flour. The water content should be close but perhaps not exactly the same.

Good idea. I will do that

I have made some progress with eliminating Kahm yeast from my own rye starter, which may be of use to posters to this thread.

I've added it to my original post and my new comment can be found here:

https://www.thefreshloaf.com/comment/539152#comment-539152

Lance

I don't know how I missed this last year. Just what I was looking for today. Thanks Doc.

I've created a new post to continue the discussion:

White frosting on firm rye sourdough | The Fresh Loaf