Sour dough can be made using the contents of probiotic capsules containing Lactic Acid Bacteria (LAB). I have made these sour doughs for a few years now and they come out nicely with just the right amount of sour that I enjoy

Roger, please post your formula and method. Once I get the proper probiotics and have the time I plan to give it a go.

I am also curious about how you came up with the probiotics capsules for LAB. I think I read elsewhere that your background was helpful. I’m a curious sort... If the bread does bake sour, this “sour head” would like to experiment with the capsules in my levain based SFSD.

Because I make this loaf using Lactic Acid producing bacteria (probiotics), I called this Bacillus Ambrosia, where "Bacillus" is a term for many of these types of bacteria. The dough will have a high hydration value 72% and resemble a Ciabatta. The probiotics can be purchased at any health food store or drug store. My method uses a stand up mixer which allows for minimal use of the hands and offers good development of gluten . The process is a 2 phase operation where 1/2 of the flour weight is fermented with the contents of 2 probiotic capsules.

It has been said that the sour dough does not necessarily apply to the sour taste of the bread but rather, a term used for the production. Our pioneer ancestors did not have access to the high quality yeast strains now available so they basically had to rely on the omnipresent wild yeast to make their bread and then strive to maintain that culture for future use. There will also be Lactic Acid producing bacteria (LAB) in the flour and depending how successful these bacteria are in the ferment process, determines the amount of "sour".

The biological process is extremely complicated and a university degree in Microbiology is required to fully understand the life cycles of these organisms. However, having a full and complete knowledge of this will probably not assist you in making a better loaf of bread. The time honored old fashioned "experience" is what it takes. I can offer this though; When the dough is being fermented, all of the organisms in the dough will be competing for the available food source (sugar) in the flour. Eventually one or more species become dominant and push out the other organisms. Yeast will probably be the dominant organism in most of the doughs with some remnants of LAB. When this happens, the amount of "sour" (Lactic Acid) the LAB produces is diminished. This is why, over time, your sour dough starter will change.

Bacillus Ambrosia: I use a weigh scale for all of my dough volumes and graduated cylinders for precise water volumes. I like to be precise and most important, consistent. I also use a yogurt maker to ferment the dough.

Total weight of flour 440gm. Water, 318ml (72% hydration), 1 1/2 tsp salt (Pickling salt, finely ground in a Mortar & Pestle), contents of 2 probiotic capsules. 2 tsp dried yeast to be used for the 2nd phase.

1st phase: Add 220gm flour to a large bowl, the salt, 253ml water (reserving 65ml or 4 1/2 tbls water) and the contents of 2 probiotic capsules. Mix well. Place the dough into a yogurt maker and allow 12 hours to ferment. If you don't use a yogurt maker, cover the bowl with plastic wrap and punch a small hole in the plastic with the point of a knife. This will allow any production gasses to escape. This must be kept in a warm place for 24 hours. This method is workable but does not offer the best temperature for the LAB.

2nd phase after 12 hours ferment: Dissolve the 2 tsp dried yeast in the reserved 65ml of warm water to activate. Pour the fermented dough into the stand mixer. (Adding the fermented dough first, allows for better mixing. Add the remaining 220gm flour and the activated yeast. Turn on the mixer and when the flour has come together, put the mixer on high speed (7 or 8) to get a good knead. You may want to hold the mixer during this to prevent it from moving.

Using a curved bread scrapper, remove the kneaded dough and put into a large bowl. Cover with plastic wrap, punch the small hole and allow 60 minutes rise or until doubled. Put a Dutch Oven in the oven and heat to 450F. A Dutch Oven isn't mandatory. After the 1st rise, use the curved bread scrapper to push, pull & lift the dough to degas. Remove the Dutch Oven from the oven and pour the dough, using the bread scraper directly into the Dutch Oven. Bake for 20 minutes with the lid on and 35-40 minutes with lid off.

I am aware. 1ml = 1gm. However, I don't trust my kitchen weigh scale for the liquid volumes. I'm a stickler for precision. It goes back to my wastewater treatment days where I had to calculate the solids values in water etc. We had a very high quality electronic weigh sale where results were in the 4th decimal place. I have the graduated cylinders on hand so I figured I may as well use them.

You wrote, “After the 1st rise, use the curved bread scrapper to push, pull & lift the dough to degas.” To make sure I understand. After the final dough is mixed let it double, then deflate the dough? Do you put the deflated dough in the hot dutch oven or do you let it rise again before putting in the Dutch Oven?

I use the curved bread scrapper to deflate the dough. The idea is to not use your hands as much as possible because its a very wet dough like a Ciabatta. After the ferment is added to the rest of the flour and after the 1st rise, I deflate it with the scrapper and push it all out right into the hot Dutch Oven. No 2nd rise. That worked for me but we'll see if it works again. I'll be making mine tomorrow after the 12 hour ferment.

Just to go over the basic steps again:

The 1st phase is the 12 hour ferment. The 2nd phase is the addition of the "activated" yeast in the 65ml of warm water and the rest of the flour. This can all be put into the Stand Mixer and kneaded until smooth which may require a high speed mix (7 or 8) after it is blended. You don't want flour explosions. Allow 1 hour to rise or until doubled. Have the oven heated to 450F with the Dutch Oven inside. After the 1st rise, it is put directly into the hot Dutch Oven. 20 minutes with the lid on and 35 - 40 minutes with the lid off.

I was concerned about adding salt to the first stage. I know that salt slows sown yeast production, but needed to google its affect on LAB. I found THIS LINK. The information was interesting. Note - I weighed your instructions (1 1/2 tsp) of pickling salt. My salt was fine and didn’t require any grinding. It was more than the typical 2% of the total flour weight, so I reduced the salt to 2%. Your coarse salt would weigh less, according to volume.

I am mixing the second stage now.

Roger how long do you wait to slice your bread? I plan to slice it using your timing. That way our comparisons will be equal.

I followed your instructions using L.planetarium 299V. Very pleased with the outcome. But from my experience with milk beverages I know that different LAB species produce different flavors.

I am curious as to what specific species you are using and if you tried any others before settling on the particular one or ones you prefer.

I used Jamieson; 5 billion probiotic and the specific LAB it contains for this purpose is "Lactococcus lactis" & "Lactobacillus gasseri" which I believe do the bull work for the ferment. But the product contains 6 specific LAB bacterium which will undoubtedly contribute.

You may be interested in a new method that I have developed and shared with others on other platforms. It is the Wheat Flour fermentation in Butter Milk. Its been a while since I have used the yogurt maker but nonetheless, I did get very pleasing results. Here is the info on this. I actually prefer this method now. It gives a tremendous sourness along with great flavours and the butter milk contains all the LSAB required. I'll be happy to assist you along the way. You need to ensure your butter milk contains live culture but I always add 2 capsules of probiotics to ensure complete fermentation.

A large 1700ml mason jar will suffice for these values

The ferment temperature is an average 25ºC

Add the flour to the butter milk and whisk smooth. Whisk until a good volume of air is introduced into the batch making it an aerobicenvironment. The added “dissolved” air will assist the yeast to grow in numbers. When the dissolved O2 is depleted, the yeast will convert the available sugars within the flour and butter milk to Alcohol (Ethanol). The now, anaerobic environment will then be favourable for the Lactic Acid Bacteria (LAB) to start fermenting the remaining available sugars within the flour and butter milk to Lactic Acid.

Slowly and gently, warm the butter milk to approximately 25°C – 27°C (Crucial step)

Blend thoroughly in the mason jar and cover lightly so as to allow gas to escape. Wild yeast within the flour and Lactic acid bacteria in the butter milk will activate. The Lactic Acid producing bacteria will eventually create enough Lactic Acid to cease the yeast activation. The final product will contain lactic acid and a small amount of alcohol. After approximately 4 days, the fermented flour settles to the bottom of the jar and leaves a small volume of cloudy supernatant (The liquid above the settled solids) above it. The mass will slowly settle leaving more supernatant. Allow the ferment to continue until the food supply is exhausted approximately (6-7) days from the start. Pour off the supernatant for use in other bread making. Keep the spent flour to make a sour dough type bread. Keep the supernatant and the spent flour in the refrigerator.

After the 4th day, the CO2 “burps” in the air lock are approximately 1 minute, 24 seconds apart. This will eventually slow down as the available food source becomes depleted. After 6-7 days, the ferment is sufficiently fermented. (Weight of Supernatant recovered + Weight of Spent Flour) after the ferment shows, a 6%-7% loss inweight due to the CO2 being expelled during the ferment. Use the fermented flour for baking bread. Making bread with this spent flour which is a sloppy liquid mass, use 50% Hydration value for the bread baking. The 50% hydration is based on the weight of the dry bread flour and not the total weight.

You can always add the contents of 2 probiotic capsules to the butter milk. It will work when your butter milk does not have active culture. I always use this even though the butter milk we have is full of live culture.

Here is a more friendly recipe for this using 1 litre of Butter milk which weighs approximately 1012g.and adding 200gm of flour.

Butter Milk Fermented Wheat Flour

Ferment:

1 litre butter milk 1012gm

200gm flour

TW 1212gm

Butter milk = 83%

Flour = 17%

Contents of 1 probiotic capsule.

A large 1700ml mason jar will suffice for these values

The ferment temperature is an average 25ºC

Add the flour to the butter milk and whisk smooth. Whisk until a good volume of air is introduced into the batch making it an aerobicenvironment. The added “dissolved” air will assist the yeast to grow in numbers. When the dissolved O2 is depleted, the yeast will convert the available sugars within the flour and butter milk to Ethanol. The now, anaerobic environment will then be favourable for the Lactic Acid Bacteria (LAB) to start fermenting the remaining available sugars within the flour and butter milk to Lactic Acid.

Slowly and gently, warm the butter milk to approximately 25°C – 27°C

Blend thoroughly in the mason jar and cover lightly so as to allow gas to escape. Wild yeast within the flour and Lactic acid bacteria in the butter milk will activate. The Lactic Acid producing bacteria will eventually create enough Lactic Acid to cease the yeast activation. The final product will contain lactic acid and a small amount of alcohol. After approximately 4 days, the fermented flour settles to the bottom of the jar and leaves a small volume of cloudy supernatant (The liquid above the settled solids) above it. The mass will slowly settle leaving more supernatant. Allow the ferment to continue until the food supply is exhausted approximately (6-7) days from the start. Pour off the supernatant for use in other bread making. Keep the spent flour to make a sour dough type bread. Keep the supernatant and the spent flour in the refrigerator.

After the 4th day, the CO2 “burps” (in the air lock which I use) are approximately 1 minute, 24 seconds apart. This will eventually slow down as the available food source becomes depleted. After 6-7 days, the ferment is sufficiently fermented. (Weight of Supernatant recovered + Weight of Spent Flour) after the ferment shows, a 6%-7% loss inweight due to the CO2 being expelled during the ferment. Use the fermented flour for baking bread. When making bread with this spent flour which is a sloppy liquid mass, use 50% Hydration value for the bread baking. The 50% hydration is based on the weight of the dry bread flour and not the total weight.

Yippee, what is CLAS? I googled it and couldn’t find an answer.

If you go to 20:26 in the video, you can see bubbles on the surface of the mixture. I wonder if he is not creating a starter. Towards the end of the video he claims that the heterofermative process is creating CO2 gas.

It was also interesting how he demonstrated the lowering of the PH after the refresh.

Thanks for sharing the link. I may never try this (who knows), but it was very interesting to watch.

I think Rus created the acronym CLAS just to use it in the translation of his procedures for English-speaking bakers. The "thing" has a different technical name in Russian.

I'll try and answer all the questions from Dan & Yippee:

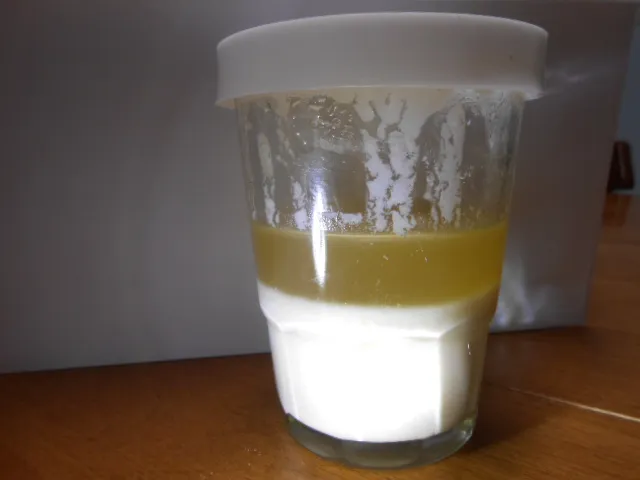

The temperature from my Yogurt maker maintains a constant 36.5C (97.7F). I get good results form this. Because I'm only using 25% of the total flour weight, I don't expect to have a problem with the loaf due to excessive breakdown of that 25%. I'll make the bread today after a 20 hiur ferment at that temperature and post the results. Here is a picture of 1 of the yogurt jars. There are 3 total for that 25% flour. The flour has settled to the bottom but is alive with LAB. You can see the yellowish liquid on the surface which I think contains a great deal of Lactic Acid. There are no bubbles visible indicating very little yeast activity. There is a small amount of foam on the surface with "very tiny" bubbles which may be CO2 from LAB activity. Tasting this liquid::Very salty with a bit of sour.

I stated earlier that the salt value in the LAB ferment was 8%. I failed to add the weight of the water which makes the salt value 2.5%. It did taste salty when I tried it.

This is another attempt to get a good LAB culture using the yogurt maker. Instead of trying extract the Lactic Acid from the flour only, I added sugar. After 24 hours, there are very tiny bubbles (CO2) within the flour itself. This indicates that the LAB is working in the flour. I have not had this reaction in my previous ferments over 12 - 12 hours. The clear liquid over the flour should contain Lactic Acid. I no longer have my titration equipment so I'll just go by the old taste test when the bread is finished. In the photo is 1 jar that fits into the yogurt maker

Image

and from my recipe there are 3 of these jars, fermented 24 hours at 37C

This is interesting Roger. If the liquid on top is lactic acid, what do you think about siphoning off the liquid and using it only for the dough. This way we can ferment stage 1 as long as we want without any concern for dough degradation.

Is the liquid a type of concentrated liquid acid?

Your thought process has broadened my horizon. With all of the ideas, experiments, thoughts that run through my head, I’m not sure that is a good thing. <I am laughing out loud!>

I think that is a good idea. However, there is one post that uses (CLAS) which I believe is Concentrated Lactic Acid. Adding this to your dough will give the sour that you want but will be lacking in the flavours that are derived from fermentation.

The liquid above the flour in the jar is not a concentration of Lactic Acid but rather, contains any Lactic Acid that has been produced (I hope). I've got the dough rising as I type this and will keep you posted. One other thing; My loaf yesterday actually stuck (a bit) to the bottom of the Dutch Oven. This was a direct result of not allowing enough heat time in the oven. The Dutch Oven was too cold. I always heat the Dutch Oven in the oven with the lid beside it to get as much heat into it as possible. Yesterday, I got caught behind in my timing and the Dutch Oven had only been in the oven for a few minutes when the oven reached 450F. It needs at least 15 minutes of heat time.

On another not Dan, I posted a reply to Yippee about the CO2 in the 1st rise. You got me thinking about that and what I'm thinking is; When the dough is degassed, the CO2 comes into contact with more water and the result may be the formation of Carbonic Acid. I'm not sure if Carbonic Acid is formed immediately when CO2 comes into contact with water but it would be interesting to know. I'm not a chemist and one would think that if this be the case, the oceans and lakes would be turning acidic if the atmosphere is infusing CO2 into them? Degassing would then mean the possibility of the pH being lowered in the dough. If lowered significantly, it could affect the 2nd rise?

“Adding this to your dough will give the sour that you want but will be lacking in the flavours that are derived from fermentation.”

My thought is to greatly reduce the commercial yeast in the final ferment in order to extend it to develop the flavors.

This thought leads to another. My evaluation of the intial test of your method mentioned a lack of complexity in the flavor. Although sour, the flavor lacked the multi-layered complexity that is derived from naturally levained sourdough. I believe the “intensity” of “sour” derived from your method is able to match sourdough. Maybe if we can extend the final fermentation much longer we can produce a more complex flavor profile.

Looking for Pros and Cons...

It is my belief that great bread MUST be fermented over a long period of time. IMO, shortcuts all fall short and fail to produce the very best flavor. If I’m wrong, I’d love to learn differently. <I feel this way about everything I belief>

I'm starting a large batch of LAB ferment right now. I'm going to collect the liquid and distill the water off and the taste test before/after will give me an idea of the Lactc Acid available. I'll let it go 24 hours and then test it. A flour/sugar ferment should offer some nice flavours.

It will work. I intend, after 24 hours to pour the liquid above the flour off into a measuring cup and sealing. I'll then take the flour and put in a screen device that separates the flour for the liquid. This device came with a second yogurt maker that I have. It is used to take the finished yogurt that you made and put into this screen. The liquid slowly drains out into a basin at the bottom leaving behind a very thick yogurt (Ztaziki) or yogurt cheese as some call it.

I'll then put this liquid into a small pot and "very slowly" heat it until there is a reduction from the water that has come off. I'll be tasting it at every point to determine if the sour is increasing.

I also enjoy this as it brings new undiscovered processes into play. I think we'll like the results when its all done. Like I stated to you before, I'm still learning this and there is always room for improvement. That is what I'm getting from our discussions.

The bake was a pleasant experience. I must say, the flavor of the matured mix in stage 1 is tasty.

Crumb shot to follow. The only issue experienced is the bread is stuck to the bottom of the pot. Hoping that when the vessel cools the bread will release. I was able to release the bread from the pot with a rubber dough scraper.

The most important part of this test will be the flavor. So far everything appeared to go extremely well, with the exception of the sticking. Roger didn’t have that problem.

I haven’t sliced or tasted the bread yet, but with the help of Roger, I think I know what needs to be done to improve the bread.

Problems

crust was pale

dough stuck badly to the bottom of the pot

Causes

The pale crust is thought to be because the stage 1 mix was fermented too warm for too long. The dough degraded grossly and the sugars necessary for browning was not available.

Roger and I think the dough stuck because the gluten was not properly developed. This was likely caused because the stage 1 mix was grossly degraded. Once mixed in the final dough, recovery of strong gluten became impossible. The final dough could best be described as thick pancake batter. Since this was my first bake I had no idea what to expect. When the batter was literally pour into the baking vessel, the bottm made such contact with the pot that sticking resulted.

Solution

I believe I completely missed the boat for the initial fermentation! 12 hours @ 94F was overkill. If the bread taste good and I decide to bake again, I plan to reduce the fermentation time for stage 1, but maintain 93F. I will also reduce the hydration for the intial stage.

The percentage of yeast will be greatly reduced to allow a longer ferment for stage 2.

Roger tells me that the dough should ball up during the final mix. This was impossible during the first bake because of the degraded gluten. If I bake again (waiting on taste test) I expect much different results, although the first bread came out resonably well given the circumstances.

Waited a day to slice so that that acids could build.

Texture and Crumb - even though the dough was grossly over proofed, the texture and crust was moderately soft, moist, and the chew was pleasant.

Taste - if the bread was compared to a commercially yeasted bread, I’d rate is ~7.5 - 8. I rarely eat yeasted bread, but if I didn’t eat SD I would like it a lot. It had a smooth sour flavor (lactic acid) that made the bread interesting to eat. It also had a nice smell, which enhanced the entire experience.

But if I compared the bread to a good sourdough it wouldn’t compete. Even though the sour was obviously present, it lacked the complexity of naturally levained SD. I judge sour tasting bread by chewing it several or more times, then expecting a burst of sour that originates on the sides at the back of the tongue. I got that sensation, but as said it lacked the complexity and intensity of a “sour” sourdough bread.

All in all this is a very nice yeasted bread, although a counterfeit. Even though it won’t pass for the original, in my opinion it is a bread that yeast bakers looking for a sour bread would probably enjoy. I think you are onto something Roger and I look forward to your improvements. This bread is worth the effort. Thanks for sharing your innovative formula amd process.

It has been 2 days since my taste test was posted. 3 days since the bread was baked.

The bread has been left out on the counter with the cut end facing down. Today I am more impressed. The crust remains moist and the flavor is very nice for a yeasted bread. My wife doesn’t like real SD at all. When I asked her to taste it, she didn’t like it. Her evaluation speaks volumes in a very positive way.

Once again, it can’t compare to SD bread, but for yeasted (CY) bread bakers this formula may be very special. Most people that taste this bread would definitely recognize the sourdough flavor. Roger is on to something.

Just wanted to thank my good friend Danny Ayo for his assistance in my process. I started out using the probiotics to obtain the sour that I desired and it worked quite well. However there was room for improvement and together, Dan and I discussed options and I now know that the yogurt maker must be used and the ferment time should be a minimum 24 hours.

Using the contents of the probiotic capsules with the yogurt maker, ensures a pure strain of Lactic Acid Bacteria (LAB) that will work on the flour. The pure and plentiful strain of LAB will start to work immediately due to the warm environment provided by the yogurt maker and the competition for the available food source will favour the LAB. This will prevent most of the wild yeast present from proliferating and this is what I want. The yeast is added at another phase for this bread production.

I watched a video that Dan sent me regarding a fellow who cultures his LAB using whole rye flour and rye malt. He also uses a yogurt maker and his process is similar other than the fact he's using flour to obtain and culture LAB. He added vinegar to the ferment to lower the pH to favour the LAB whereas my process doesn't require a lowered pH value to start with. This is due to the LAB, in its pure form, working almost immediately, forming Lactic Acid which itself will lower the pH naturally. I do however use a small amount of sugar to the ferment to provide a valuable food source for the LAB and hopefully get converted to Lactic Acid. The sweetness in finished product is not detected. The other aforementioned method also stated in the video that if the end result does not taste good, throw it out and start again. To me, the process may be prone to upset from a total reliance on the organisms within the flour. Obviously the preferred selection of organism may not take hold in the ferment. Using probiotics removes this uncertainty.

I'm still working on it but just wanted to thank Dan again for his interest and all of his very helpful input.

Here is the finished loaf. Dan was correct. the 50/50 flour ration saw a degradation in the flour but still turned out OK. Here is a photo of the finished loaf with 25% of the total flour weight fermented. There is a significant increase in the rise.

There is a definite difference in flavour and sour but I want more sour. What I'm doing right now is; I've got a new batch (1st phase) going with sugar added. The 1st phase dough (253ml water, 110gm flour, the contents of the 2 probiotic capsules + 15gm sugar). After talking with Dan, I decided to go back to my roots and culture the LAB in this way. I'm hoping the LAB will consume most of the sugar in the yogurt fermenter (24 hours) as well as some of the sugar in the flour. Previously, I was hoping to get the Lactic Acid from the flour only but I want more. If I get a 50% ferment from those sugars (8gm at least), that will basically mean 8gm of lactic acid produced = 1% Lactic Acid to the total weight. That would mean a great deal of sour.

On another note; I also discussed with Dan, the reaction of CO2 being produced in regular bread making and what effect it has when the dough is degassed )punched down). When CO2 is present and comes into contact with water, Carbonic Acid is produced and this would ultimately decrease the pH value., Will this happen when the dough is degassed? I'd like to have a conversation on this topic with someone experienced in this.

I'm going all out on my new ferment starting right now. I'm LAB fermenting 25% of the total flour weight with the same volume of water (Makes it more watery), the same volume of salt (LAB loves the salt) and the contents of 2 capsule of the probiotics. I'm fermenting this for 18 hours.

Objective; create as much Lactic Acid as possible. Using only 25% of the total flour weight and LAB fermenting for 18 hours will probably destroy the consistency of the flour but its only 25% of the total. Will report the results tomorrow.

Salt makes up an important part of bread recipes. Salt makes an agreeable environment for the LAB where most other form of bacteria cannot tolerate. Since I only used 25% of the total flour weight for my LAB ferment, this would elevate the salt value in that smaller flour volume. The salt would be approximately 9gm and that to 110gm flour = 8% which is quite high but not for the "finished" loaf. The average salt value for bread is approximately 2% I believe.

The initial high salt value would assist in the LAB growing but at the expense of any wild yeast present which is what I want. I want the LAB to grow but not the yeast. About 15 hours have gone by right now and I don't see any gas bubbles in the ferment as I've seen in the past. This is a good indication that there is no yeast activity.

I may let this ferment go for 20 hours or more just to see how much Lactic Acid I'm able to extract from this 110gm of flour.

Roger, as you know I am following your results. You mentioned 25% of the total flour prefermented for 18 hours. But, in order to tell the whole story we need to know the temperature. I predict that your experiment will produce a very acidic and weak dough. And, if I am correct, the introduction of the first ferment into the final dough will produce a bread somewhat similar to mine. But, all of that depends on your temperature during fermentation. Whether the prediction is correct or not, I look forward to learning from your test.

Am I correct to assume that your method of an extremely wet initial hydration is to provide an environment for maximum lactic acid production?

Like Yippee, I too was concerned about the addition of salt in the initial ferment. But when you explain that there should be no yeast in the first ferment it makes sense. We think in terms of sourdough culture.

Let me take this opportunity to bragg about Roger. He is definitely not a novice when it comes to fermentation. I found THIS ARTICLE online. His experience with fermentation is an assest that can benefit sourdough bakers.

I just wanted to confirm ???. Both Roger and Rus (R&R???)are separating the lactic acid and yeast fermentation in two stages. Remember I told you the "thing" is yeast-free? Phase 1 is mainly for cultivating the flavor-enhancing "thing". Phase 2 is for leavening by commercial yeast. Right, Roger?

Roger, please post your formula and method. Once I get the proper probiotics and have the time I plan to give it a go.

I am also curious about how you came up with the probiotics capsules for LAB. I think I read elsewhere that your background was helpful. I’m a curious sort... If the bread does bake sour, this “sour head” would like to experiment with the capsules in my levain based SFSD.

Dan

Because I make this loaf using Lactic Acid producing bacteria (probiotics), I called this Bacillus Ambrosia, where "Bacillus" is a term for many of these types of bacteria. The dough will have a high hydration value 72% and resemble a Ciabatta. The probiotics can be purchased at any health food store or drug store. My method uses a stand up mixer which allows for minimal use of the hands and offers good development of gluten . The process is a 2 phase operation where 1/2 of the flour weight is fermented with the contents of 2 probiotic capsules.

It has been said that the sour dough does not necessarily apply to the sour taste of the bread but rather, a term used for the production. Our pioneer ancestors did not have access to the high quality yeast strains now available so they basically had to rely on the omnipresent wild yeast to make their bread and then strive to maintain that culture for future use. There will also be Lactic Acid producing bacteria (LAB) in the flour and depending how successful these bacteria are in the ferment process, determines the amount of "sour".

The biological process is extremely complicated and a university degree in Microbiology is required to fully understand the life cycles of these organisms. However, having a full and complete knowledge of this will probably not assist you in making a better loaf of bread. The time honored old fashioned "experience" is what it takes. I can offer this though; When the dough is being fermented, all of the organisms in the dough will be competing for the available food source (sugar) in the flour. Eventually one or more species become dominant and push out the other organisms. Yeast will probably be the dominant organism in most of the doughs with some remnants of LAB. When this happens, the amount of "sour" (Lactic Acid) the LAB produces is diminished. This is why, over time, your sour dough starter will change.

Bacillus Ambrosia: I use a weigh scale for all of my dough volumes and graduated cylinders for precise water volumes. I like to be precise and most important, consistent. I also use a yogurt maker to ferment the dough.

Total weight of flour 440gm. Water, 318ml (72% hydration), 1 1/2 tsp salt (Pickling salt, finely ground in a Mortar & Pestle), contents of 2 probiotic capsules. 2 tsp dried yeast to be used for the 2nd phase.

1st phase: Add 220gm flour to a large bowl, the salt, 253ml water (reserving 65ml or 4 1/2 tbls water) and the contents of 2 probiotic capsules. Mix well. Place the dough into a yogurt maker and allow 12 hours to ferment. If you don't use a yogurt maker, cover the bowl with plastic wrap and punch a small hole in the plastic with the point of a knife. This will allow any production gasses to escape. This must be kept in a warm place for 24 hours. This method is workable but does not offer the best temperature for the LAB.

2nd phase after 12 hours ferment: Dissolve the 2 tsp dried yeast in the reserved 65ml of warm water to activate. Pour the fermented dough into the stand mixer. (Adding the fermented dough first, allows for better mixing. Add the remaining 220gm flour and the activated yeast. Turn on the mixer and when the flour has come together, put the mixer on high speed (7 or 8) to get a good knead. You may want to hold the mixer during this to prevent it from moving.

Using a curved bread scrapper, remove the kneaded dough and put into a large bowl. Cover with plastic wrap, punch the small hole and allow 60 minutes rise or until doubled. Put a Dutch Oven in the oven and heat to 450F. A Dutch Oven isn't mandatory. After the 1st rise, use the curved bread scrapper to push, pull & lift the dough to degas. Remove the Dutch Oven from the oven and pour the dough, using the bread scraper directly into the Dutch Oven. Bake for 20 minutes with the lid on and 35-40 minutes with lid off.

Cheers

roger

Roger, are you aware that 253ml equals 253 grams? This might make weighing a little easier.

HTH

DNny

I am aware. 1ml = 1gm. However, I don't trust my kitchen weigh scale for the liquid volumes. I'm a stickler for precision. It goes back to my wastewater treatment days where I had to calculate the solids values in water etc. We had a very high quality electronic weigh sale where results were in the 4th decimal place. I have the graduated cylinders on hand so I figured I may as well use them.

Thanks for the interest

roger

Roger, it was good to talk with you.

You wrote, “After the 1st rise, use the curved bread scrapper to push, pull & lift the dough to degas.” To make sure I understand. After the final dough is mixed let it double, then deflate the dough? Do you put the deflated dough in the hot dutch oven or do you let it rise again before putting in the Dutch Oven?

I will be baking this tomorrow.

Danny

I use the curved bread scrapper to deflate the dough. The idea is to not use your hands as much as possible because its a very wet dough like a Ciabatta. After the ferment is added to the rest of the flour and after the 1st rise, I deflate it with the scrapper and push it all out right into the hot Dutch Oven. No 2nd rise. That worked for me but we'll see if it works again. I'll be making mine tomorrow after the 12 hour ferment.

Just to go over the basic steps again:

The 1st phase is the 12 hour ferment. The 2nd phase is the addition of the "activated" yeast in the 65ml of warm water and the rest of the flour. This can all be put into the Stand Mixer and kneaded until smooth which may require a high speed mix (7 or 8) after it is blended. You don't want flour explosions. Allow 1 hour to rise or until doubled. Have the oven heated to 450F with the Dutch Oven inside. After the 1st rise, it is put directly into the hot Dutch Oven. 20 minutes with the lid on and 35 - 40 minutes with the lid off.

I was concerned about adding salt to the first stage. I know that salt slows sown yeast production, but needed to google its affect on LAB. I found THIS LINK. The information was interesting. Note - I weighed your instructions (1 1/2 tsp) of pickling salt. My salt was fine and didn’t require any grinding. It was more than the typical 2% of the total flour weight, so I reduced the salt to 2%. Your coarse salt would weigh less, according to volume.

I am mixing the second stage now.

Roger how long do you wait to slice your bread? I plan to slice it using your timing. That way our comparisons will be equal.

Danny

What probiotics? There are thousands to choose from.

Any brand that can be trusted to be of high quality. They all usually contain many of the the Lactic Acid Bacteria "LAB" that is required.

Thanks for your reply.

I followed your instructions using L.planetarium 299V. Very pleased with the outcome. But from my experience with milk beverages I know that different LAB species produce different flavors.

I am curious as to what specific species you are using and if you tried any others before settling on the particular one or ones you prefer.

I used Jamieson; 5 billion probiotic and the specific LAB it contains for this purpose is "Lactococcus lactis" & "Lactobacillus gasseri" which I believe do the bull work for the ferment. But the product contains 6 specific LAB bacterium which will undoubtedly contribute.

You may be interested in a new method that I have developed and shared with others on other platforms. It is the Wheat Flour fermentation in Butter Milk. Its been a while since I have used the yogurt maker but nonetheless, I did get very pleasing results. Here is the info on this. I actually prefer this method now. It gives a tremendous sourness along with great flavours and the butter milk contains all the LSAB required. I'll be happy to assist you along the way. You need to ensure your butter milk contains live culture but I always add 2 capsules of probiotics to ensure complete fermentation.

Butter Milk Fermented Wheat Flour

Ferment:

First, determine the Total Weight (TW)

Example: 1275gm TW

84% Butter Milk (1275gm)(0.84) = 1071gm butter milk

16% Bread Flour (1275)(0.16) = 204gm flour

A large 1700ml mason jar will suffice for these values

The ferment temperature is an average 25ºC

Add the flour to the butter milk and whisk smooth. Whisk until a good volume of air is introduced into the batch making it an aerobic environment. The added “dissolved” air will assist the yeast to grow in numbers. When the dissolved O2 is depleted, the yeast will convert the available sugars within the flour and butter milk to Alcohol (Ethanol). The now, anaerobic environment will then be favourable for the Lactic Acid Bacteria (LAB) to start fermenting the remaining available sugars within the flour and butter milk to Lactic Acid.

Slowly and gently, warm the butter milk to approximately 25°C – 27°C (Crucial step)

Blend thoroughly in the mason jar and cover lightly so as to allow gas to escape. Wild yeast within the flour and Lactic acid bacteria in the butter milk will activate. The Lactic Acid producing bacteria will eventually create enough Lactic Acid to cease the yeast activation. The final product will contain lactic acid and a small amount of alcohol. After approximately 4 days, the fermented flour settles to the bottom of the jar and leaves a small volume of cloudy supernatant (The liquid above the settled solids) above it. The mass will slowly settle leaving more supernatant. Allow the ferment to continue until the food supply is exhausted approximately (6-7) days from the start. Pour off the supernatant for use in other bread making. Keep the spent flour to make a sour dough type bread. Keep the supernatant and the spent flour in the refrigerator.

After the 4th day, the CO2 “burps” in the air lock are approximately 1 minute, 24 seconds apart. This will eventually slow down as the available food source becomes depleted. After 6-7 days, the ferment is sufficiently fermented. (Weight of Supernatant recovered + Weight of Spent Flour) after the ferment shows, a 6%-7% loss in weight due to the CO2 being expelled during the ferment. Use the fermented flour for baking bread. Making bread with this spent flour which is a sloppy liquid mass, use 50% Hydration value for the bread baking. The 50% hydration is based on the weight of the dry bread flour and not the total weight.

Checked, no active butter milk available locally. Expect Whole Foods will have it. Will check next time I'm in Dallas.

until then I may try following your instructions substitutions kefir for the butter milk. I will let you know what happens.

You can always add the contents of 2 probiotic capsules to the butter milk. It will work when your butter milk does not have active culture. I always use this even though the butter milk we have is full of live culture.

Here is a more friendly recipe for this using 1 litre of Butter milk which weighs approximately 1012g.and adding 200gm of flour.

Butter Milk Fermented Wheat Flour

Ferment:

1 litre butter milk 1012gm

200gm flour

TW 1212gm

Butter milk = 83%

Flour = 17%

Contents of 1 probiotic capsule.

A large 1700ml mason jar will suffice for these values

The ferment temperature is an average 25ºC

Add the flour to the butter milk and whisk smooth. Whisk until a good volume of air is introduced into the batch making it an aerobic environment. The added “dissolved” air will assist the yeast to grow in numbers. When the dissolved O2 is depleted, the yeast will convert the available sugars within the flour and butter milk to Ethanol. The now, anaerobic environment will then be favourable for the Lactic Acid Bacteria (LAB) to start fermenting the remaining available sugars within the flour and butter milk to Lactic Acid.

Slowly and gently, warm the butter milk to approximately 25°C – 27°C

Blend thoroughly in the mason jar and cover lightly so as to allow gas to escape. Wild yeast within the flour and Lactic acid bacteria in the butter milk will activate. The Lactic Acid producing bacteria will eventually create enough Lactic Acid to cease the yeast activation. The final product will contain lactic acid and a small amount of alcohol. After approximately 4 days, the fermented flour settles to the bottom of the jar and leaves a small volume of cloudy supernatant (The liquid above the settled solids) above it. The mass will slowly settle leaving more supernatant. Allow the ferment to continue until the food supply is exhausted approximately (6-7) days from the start. Pour off the supernatant for use in other bread making. Keep the spent flour to make a sour dough type bread. Keep the supernatant and the spent flour in the refrigerator.

After the 4th day, the CO2 “burps” (in the air lock which I use) are approximately 1 minute, 24 seconds apart. This will eventually slow down as the available food source becomes depleted. After 6-7 days, the ferment is sufficiently fermented. (Weight of Supernatant recovered + Weight of Spent Flour) after the ferment shows, a 6%-7% loss in weight due to the CO2 being expelled during the ferment. Use the fermented flour for baking bread. When making bread with this spent flour which is a sloppy liquid mass, use 50% Hydration value for the bread baking. The 50% hydration is based on the weight of the dry bread flour and not the total weight.

Both you and another baker are wise guys because you've employed similar strategies! Welcome to TFL, Roger! ???

Yippee

Yippee, what is CLAS? I googled it and couldn’t find an answer.

If you go to 20:26 in the video, you can see bubbles on the surface of the mixture. I wonder if he is not creating a starter. Towards the end of the video he claims that the heterofermative process is creating CO2 gas.

It was also interesting how he demonstrated the lowering of the PH after the refresh.

Thanks for sharing the link. I may never try this (who knows), but it was very interesting to watch.

Danny

that imparts tangy flavours to your bread, and I might have mistakenly called it a "starter". ???

Yippee

CLASS I believe is: "Concentrated Lactic Acid" (S)?

Thanks, that makes sense.

I think Rus created the acronym CLAS just to use it in the translation of his procedures for English-speaking bakers. The "thing" has a different technical name in Russian.

Yippee

I found that definition of CLAS.

After first refreshment pH drops to 3.6-3.8 and we will get what is in Russia called concentrated lactic acid sourdough (CLAS).

Other usful information can be found here. https://brotgost.blogspot.com/p/clas.html

My second loaf just out of the oven. 45 minutes for the "lid off" was a bit too long. 40 minutes would probably have been better.

Image

I personally love the color and shape. IMO, it is beautiful!

I also like the crackly crust which reminds me of Dutch crunch.

I'll try and answer all the questions from Dan & Yippee:

The temperature from my Yogurt maker maintains a constant 36.5C (97.7F). I get good results form this. Because I'm only using 25% of the total flour weight, I don't expect to have a problem with the loaf due to excessive breakdown of that 25%. I'll make the bread today after a 20 hiur ferment at that temperature and post the results. Here is a picture of 1 of the yogurt jars. There are 3 total for that 25% flour. The flour has settled to the bottom but is alive with LAB. You can see the yellowish liquid on the surface which I think contains a great deal of Lactic Acid. There are no bubbles visible indicating very little yeast activity. There is a small amount of foam on the surface with "very tiny" bubbles which may be CO2 from LAB activity. Tasting this liquid::Very salty with a bit of sour.

Image

I stated earlier that the salt value in the LAB ferment was 8%. I failed to add the weight of the water which makes the salt value 2.5%. It did taste salty when I tried it.

This is another attempt to get a good LAB culture using the yogurt maker. Instead of trying extract the Lactic Acid from the flour only, I added sugar. After 24 hours, there are very tiny bubbles (CO2) within the flour itself. This indicates that the LAB is working in the flour. I have not had this reaction in my previous ferments over 12 - 12 hours. The clear liquid over the flour should contain Lactic Acid. I no longer have my titration equipment so I'll just go by the old taste test when the bread is finished. In the photo is 1 jar that fits into the yogurt maker

Image

and from my recipe there are 3 of these jars, fermented 24 hours at 37C

This is interesting Roger. If the liquid on top is lactic acid, what do you think about siphoning off the liquid and using it only for the dough. This way we can ferment stage 1 as long as we want without any concern for dough degradation.

Is the liquid a type of concentrated liquid acid?

Your thought process has broadened my horizon. With all of the ideas, experiments, thoughts that run through my head, I’m not sure that is a good thing. <I am laughing out loud!>

I think that is a good idea. However, there is one post that uses (CLAS) which I believe is Concentrated Lactic Acid. Adding this to your dough will give the sour that you want but will be lacking in the flavours that are derived from fermentation.

The liquid above the flour in the jar is not a concentration of Lactic Acid but rather, contains any Lactic Acid that has been produced (I hope). I've got the dough rising as I type this and will keep you posted. One other thing; My loaf yesterday actually stuck (a bit) to the bottom of the Dutch Oven. This was a direct result of not allowing enough heat time in the oven. The Dutch Oven was too cold. I always heat the Dutch Oven in the oven with the lid beside it to get as much heat into it as possible. Yesterday, I got caught behind in my timing and the Dutch Oven had only been in the oven for a few minutes when the oven reached 450F. It needs at least 15 minutes of heat time.

On another not Dan, I posted a reply to Yippee about the CO2 in the 1st rise. You got me thinking about that and what I'm thinking is; When the dough is degassed, the CO2 comes into contact with more water and the result may be the formation of Carbonic Acid. I'm not sure if Carbonic Acid is formed immediately when CO2 comes into contact with water but it would be interesting to know. I'm not a chemist and one would think that if this be the case, the oceans and lakes would be turning acidic if the atmosphere is infusing CO2 into them? Degassing would then mean the possibility of the pH being lowered in the dough. If lowered significantly, it could affect the 2nd rise?

“Adding this to your dough will give the sour that you want but will be lacking in the flavours that are derived from fermentation.”

My thought is to greatly reduce the commercial yeast in the final ferment in order to extend it to develop the flavors.

This thought leads to another. My evaluation of the intial test of your method mentioned a lack of complexity in the flavor. Although sour, the flavor lacked the multi-layered complexity that is derived from naturally levained sourdough. I believe the “intensity” of “sour” derived from your method is able to match sourdough. Maybe if we can extend the final fermentation much longer we can produce a more complex flavor profile.

Looking for Pros and Cons...

It is my belief that great bread MUST be fermented over a long period of time. IMO, shortcuts all fall short and fail to produce the very best flavor. If I’m wrong, I’d love to learn differently. <I feel this way about everything I belief>

Danny

I'm starting a large batch of LAB ferment right now. I'm going to collect the liquid and distill the water off and the taste test before/after will give me an idea of the Lactc Acid available. I'll let it go 24 hours and then test it. A flour/sugar ferment should offer some nice flavours.

I’m curious, how do you plan to distill the liquid?

I am excited to see where this is going... Even if it ends in a dead end (as do most of my ideas) the journey is sweet.

It will work. I intend, after 24 hours to pour the liquid above the flour off into a measuring cup and sealing. I'll then take the flour and put in a screen device that separates the flour for the liquid. This device came with a second yogurt maker that I have. It is used to take the finished yogurt that you made and put into this screen. The liquid slowly drains out into a basin at the bottom leaving behind a very thick yogurt (Ztaziki) or yogurt cheese as some call it.

I'll then put this liquid into a small pot and "very slowly" heat it until there is a reduction from the water that has come off. I'll be tasting it at every point to determine if the sour is increasing.

I also enjoy this as it brings new undiscovered processes into play. I think we'll like the results when its all done. Like I stated to you before, I'm still learning this and there is always room for improvement. That is what I'm getting from our discussions.

roger

The bake was a pleasant experience. I must say, the flavor of the matured mix in stage 1 is tasty.

Crumb shot to follow. The only issue experienced is the bread is stuck to the bottom of the pot. Hoping that when the vessel cools the bread will release. I was able to release the bread from the pot with a rubber dough scraper.

The most important part of this test will be the flavor. So far everything appeared to go extremely well, with the exception of the sticking. Roger didn’t have that problem.

Danny

I haven’t sliced or tasted the bread yet, but with the help of Roger, I think I know what needs to be done to improve the bread.

Problems

Causes

Solution

Roger tells me that the dough should ball up during the final mix. This was impossible during the first bake because of the degraded gluten. If I bake again (waiting on taste test) I expect much different results, although the first bread came out resonably well given the circumstances.

Danny

Test Bake #1

Waited a day to slice so that that acids could build.

Texture and Crumb - even though the dough was grossly over proofed, the texture and crust was moderately soft, moist, and the chew was pleasant.

Taste - if the bread was compared to a commercially yeasted bread, I’d rate is ~7.5 - 8. I rarely eat yeasted bread, but if I didn’t eat SD I would like it a lot. It had a smooth sour flavor (lactic acid) that made the bread interesting to eat. It also had a nice smell, which enhanced the entire experience.

But if I compared the bread to a good sourdough it wouldn’t compete. Even though the sour was obviously present, it lacked the complexity of naturally levained SD. I judge sour tasting bread by chewing it several or more times, then expecting a burst of sour that originates on the sides at the back of the tongue. I got that sensation, but as said it lacked the complexity and intensity of a “sour” sourdough bread.

All in all this is a very nice yeasted bread, although a counterfeit. Even though it won’t pass for the original, in my opinion it is a bread that yeast bakers looking for a sour bread would probably enjoy. I think you are onto something Roger and I look forward to your improvements. This bread is worth the effort. Thanks for sharing your innovative formula amd process.

Danny

It has been 2 days since my taste test was posted. 3 days since the bread was baked.

The bread has been left out on the counter with the cut end facing down. Today I am more impressed. The crust remains moist and the flavor is very nice for a yeasted bread. My wife doesn’t like real SD at all. When I asked her to taste it, she didn’t like it. Her evaluation speaks volumes in a very positive way.

Once again, it can’t compare to SD bread, but for yeasted (CY) bread bakers this formula may be very special. Most people that taste this bread would definitely recognize the sourdough flavor. Roger is on to something.

Dan

Just wanted to thank my good friend Danny Ayo for his assistance in my process. I started out using the probiotics to obtain the sour that I desired and it worked quite well. However there was room for improvement and together, Dan and I discussed options and I now know that the yogurt maker must be used and the ferment time should be a minimum 24 hours.

Using the contents of the probiotic capsules with the yogurt maker, ensures a pure strain of Lactic Acid Bacteria (LAB) that will work on the flour. The pure and plentiful strain of LAB will start to work immediately due to the warm environment provided by the yogurt maker and the competition for the available food source will favour the LAB. This will prevent most of the wild yeast present from proliferating and this is what I want. The yeast is added at another phase for this bread production.

I watched a video that Dan sent me regarding a fellow who cultures his LAB using whole rye flour and rye malt. He also uses a yogurt maker and his process is similar other than the fact he's using flour to obtain and culture LAB. He added vinegar to the ferment to lower the pH to favour the LAB whereas my process doesn't require a lowered pH value to start with. This is due to the LAB, in its pure form, working almost immediately, forming Lactic Acid which itself will lower the pH naturally. I do however use a small amount of sugar to the ferment to provide a valuable food source for the LAB and hopefully get converted to Lactic Acid. The sweetness in finished product is not detected. The other aforementioned method also stated in the video that if the end result does not taste good, throw it out and start again. To me, the process may be prone to upset from a total reliance on the organisms within the flour. Obviously the preferred selection of organism may not take hold in the ferment. Using probiotics removes this uncertainty.

I'm still working on it but just wanted to thank Dan again for his interest and all of his very helpful input.

Roger

I'm attaching a photo of my dough when it has been beaten up by the Stand Mixer at high speed and the second photo is after 1 hour rise

Image

Image

Here is the finished loaf. Dan was correct. the 50/50 flour ration saw a degradation in the flour but still turned out OK. Here is a photo of the finished loaf with 25% of the total flour weight fermented. There is a significant increase in the rise.

Image

It's crucial to find the sweet spot where all conditions are optimal. Looks like you've found it! Any difference in flavors between the loaves?

Yippee

There is a definite difference in flavour and sour but I want more sour. What I'm doing right now is; I've got a new batch (1st phase) going with sugar added. The 1st phase dough (253ml water, 110gm flour, the contents of the 2 probiotic capsules + 15gm sugar). After talking with Dan, I decided to go back to my roots and culture the LAB in this way. I'm hoping the LAB will consume most of the sugar in the yogurt fermenter (24 hours) as well as some of the sugar in the flour. Previously, I was hoping to get the Lactic Acid from the flour only but I want more. If I get a 50% ferment from those sugars (8gm at least), that will basically mean 8gm of lactic acid produced = 1% Lactic Acid to the total weight. That would mean a great deal of sour.

On another note; I also discussed with Dan, the reaction of CO2 being produced in regular bread making and what effect it has when the dough is degassed )punched down). When CO2 is present and comes into contact with water, Carbonic Acid is produced and this would ultimately decrease the pH value., Will this happen when the dough is degassed? I'd like to have a conversation on this topic with someone experienced in this.

when you get the tanginess you want! Thanks for sharing your procedures with us.

Yippee

I'm going all out on my new ferment starting right now. I'm LAB fermenting 25% of the total flour weight with the same volume of water (Makes it more watery), the same volume of salt (LAB loves the salt) and the contents of 2 capsule of the probiotics. I'm fermenting this for 18 hours.

Objective; create as much Lactic Acid as possible. Using only 25% of the total flour weight and LAB fermenting for 18 hours will probably destroy the consistency of the flour but its only 25% of the total. Will report the results tomorrow.

in phase 1❓❓❓Thanks.

Yippee

Salt makes up an important part of bread recipes. Salt makes an agreeable environment for the LAB where most other form of bacteria cannot tolerate. Since I only used 25% of the total flour weight for my LAB ferment, this would elevate the salt value in that smaller flour volume. The salt would be approximately 9gm and that to 110gm flour = 8% which is quite high but not for the "finished" loaf. The average salt value for bread is approximately 2% I believe.

The initial high salt value would assist in the LAB growing but at the expense of any wild yeast present which is what I want. I want the LAB to grow but not the yeast. About 15 hours have gone by right now and I don't see any gas bubbles in the ferment as I've seen in the past. This is a good indication that there is no yeast activity.

I may let this ferment go for 20 hours or more just to see how much Lactic Acid I'm able to extract from this 110gm of flour.

roger

Just as I speculated ???

Yippee

Roger, as you know I am following your results. You mentioned 25% of the total flour prefermented for 18 hours. But, in order to tell the whole story we need to know the temperature. I predict that your experiment will produce a very acidic and weak dough. And, if I am correct, the introduction of the first ferment into the final dough will produce a bread somewhat similar to mine. But, all of that depends on your temperature during fermentation. Whether the prediction is correct or not, I look forward to learning from your test.

Am I correct to assume that your method of an extremely wet initial hydration is to provide an environment for maximum lactic acid production?

Like Yippee, I too was concerned about the addition of salt in the initial ferment. But when you explain that there should be no yeast in the first ferment it makes sense. We think in terms of sourdough culture.

Let me take this opportunity to bragg about Roger. He is definitely not a novice when it comes to fermentation. I found THIS ARTICLE online. His experience with fermentation is an assest that can benefit sourdough bakers.

Danny

I just wanted to confirm ???. Both Roger and Rus (R&R???)are separating the lactic acid and yeast fermentation in two stages. Remember I told you the "thing" is yeast-free? Phase 1 is mainly for cultivating the flavor-enhancing "thing". Phase 2 is for leavening by commercial yeast. Right, Roger?

Yippee

I prefer the 1st phase to be yeast free. I add the commercial yeast at the 2nd phase. Total control over both phases.

Butter milk Fermented bread:

440gm flour total weight

30%/70% ratio:

30% 132gm flour under LAB ferment

70% 308gm flour under Yeast ferment

243ml Butter milk (226gm)

1½ tsp salt

Ferment at room temperature for 24 hours covered with cling wrap.

65ml warm water for yeast activation.

Add the remainder of the flour 308gm, the activated yeast and salt

Knead in a KitchenAid mixer until very smooth

1 hour rise or until doubled.

With a bread scraper, work the dough until degassed. Allow 10 minutes rest

Pour into heated Dutch Oven

Bake at 450F in a Dutch Oven 25 minutes with lid on, 25 minutes lid off.